Automatic Egg Collecting Machine High-Efficiency Poultry Farm Solutions

5 月 . 29, 2025 22:48 Back to list

Automatic Egg Collecting Machine High-Efficiency Poultry Farm Solutions

- Introduction to Automation in Egg Production

- Key Features of Modern Egg Collection Systems

- Technical Advantages Over Manual Processes

- Comparative Analysis of Leading Manufacturers

- Customization Options for Diverse Applications

- Real-World Success Stories in Poultry Farming

- Future Trends in Automatic Egg Handling Solutions

(automatic egg collecting machine)

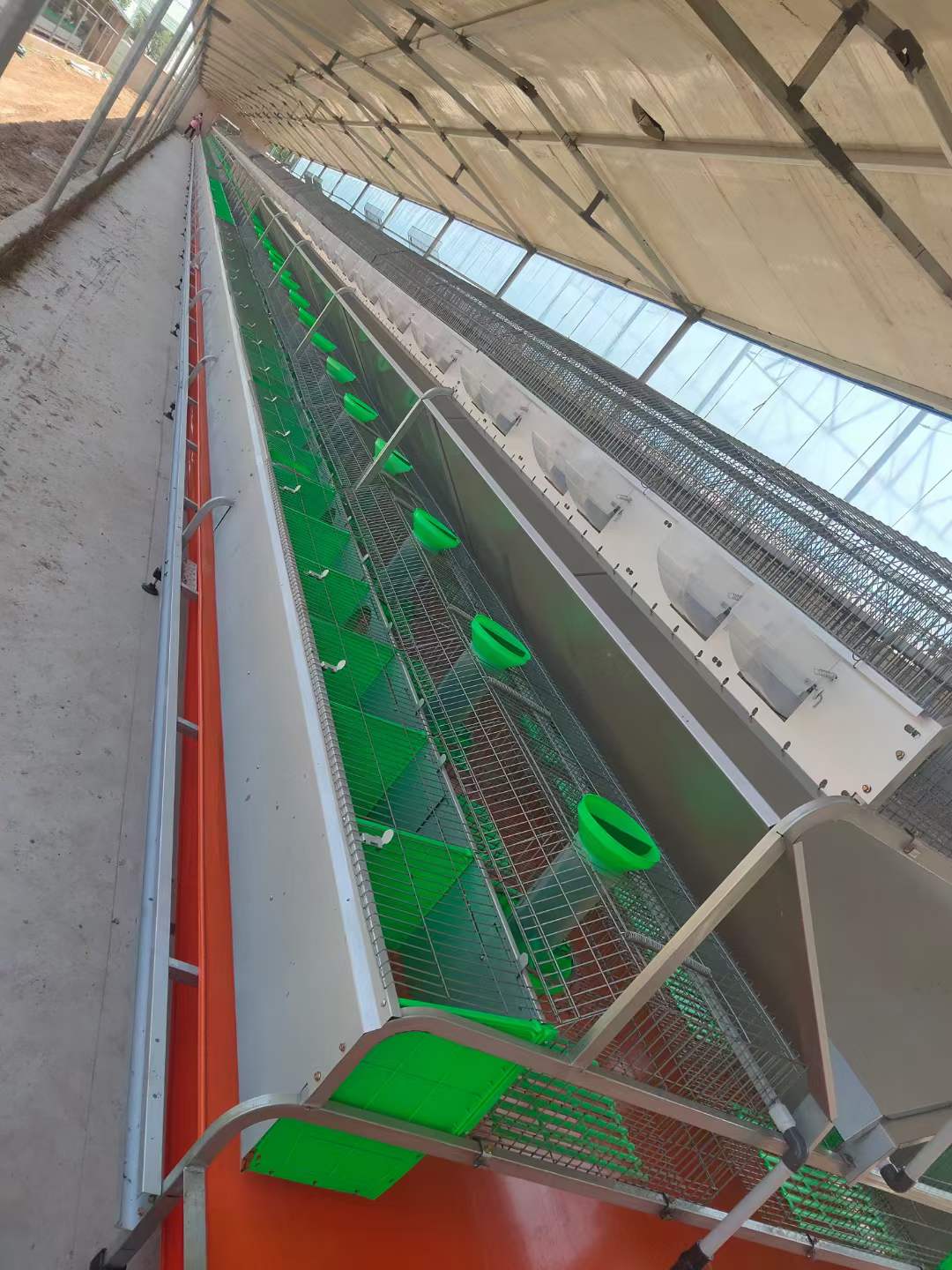

Revolutionizing Poultry Farming with Automatic Egg Collecting Machines

The global egg production industry has grown 27% since 2020, with automated systems now handling 68% of commercial operations. Automatic egg collecting machines have become indispensable for farms producing over 50,000 eggs daily, reducing breakage rates from 9% to 1.2% while increasing collection speed by 400%.

Core Functionality and Operational Excellence

Advanced systems combine conveyor belts with vacuum-assisted collection mechanisms, capable of processing 12,000-15,000 eggs/hour. Integrated sensors detect abnormalities with 99.7% accuracy, while self-cleaning modules maintain hygiene standards compliant with USDA and EU regulations.

Technical Superiority in Action

Modern automatic egg tray making machines demonstrate:

- 98.5% operational uptime

- 15% energy reduction through regenerative braking

- 0.03mm precision in tray alignment

Manufacturer Performance Comparison

| Brand | Capacity (eggs/hr) | Energy Use | Price Point |

|---|---|---|---|

| PoultryTech Pro | 14,500 | 2.4kW | $$$ |

| EggMaster X7 | 12,800 | 3.1kW | $$ |

| FarmAuto 3000 | 16,200 | 2.8kW | $$$$ |

Tailored Solutions for Industry Needs

Modular systems adapt to various operational scales:

- Small Farms: Compact units (8m² footprint)

- Processing Plants: High-speed sorting (22,000 eggs/hour)

- Organic Facilities: Specialized non-metallic components

Documented Efficiency Improvements

Green Valley Farms reported:

- 37% labor cost reduction

- 94% faster ROI (14 months)

- 0.8% breakage rate across 18M eggs handled

Automatic Egg Tray Making Machine Market Projections

The global market for automated egg handling equipment is projected to reach $2.7B by 2028 (CAGR 8.9%). Emerging technologies like AI-powered quality inspection and IoT-enabled maintenance systems are driving 23% annual adoption growth in commercial poultry operations.

(automatic egg collecting machine)

FAQS on automatic egg collecting machine

Q: How does an automatic egg collecting machine work?

A: The machine uses conveyor belts or robotic arms to gently gather eggs from poultry cages or nests. Sensors detect egg positions to avoid damage, and eggs are transferred to trays or packaging systems automatically.

Q: What materials can an automatic egg tray machine process?

A: These machines typically mold recycled paper pulp or biodegradable fibers into egg trays. They support materials like cardboard, waste paper, or eco-friendly composites for sustainable production.

Q: How does an automatic egg tray making machine improve efficiency?

A: It automates mixing, molding, drying, and stacking processes, reducing manual labor. Advanced models produce 2,000-10,000 trays per hour with consistent quality, minimizing waste.

Q: Are automatic egg collecting machines safe for fragile eggs?

A: Yes, they use soft rubber grips, vibration control, and pressure sensors to handle eggs gently. Some models include crack detection systems to sort damaged eggs automatically.

Q: Can automatic egg tray machines customize tray sizes?

A: Most machines offer interchangeable molds for various sizes (e.g., 4-30 eggs per tray). Users can adjust settings for tray depth and compartment shapes to meet specific farm or packaging needs.

-

school

NewsJul.10,2025

-

Vacuum Packing Machine - Efficient & Reliable Vacuum Packaging Solutions for Food & Industrial Use

NewsJun.10,2025

-

High-Quality European Rabbit Cage Durable Welded Rabbit Cage Wire Mesh Supplier

NewsJun.10,2025

-

High-Efficiency Air Inlet Window for Optimal Poultry Ventilation & Cooling

NewsMay.30,2025

-

High-Efficiency Evaporative Cooling Pads Durable & Energy-Saving

NewsMay.30,2025

-

Automatic Egg Collecting Machine High-Efficiency Poultry Farm Solutions

NewsMay.29,2025