Premium Breeding Environment Equipment & Farm Solutions Durable & Efficient

4 月 . 15, 2025 11:07 Back to list

Premium Breeding Environment Equipment & Farm Solutions Durable & Efficient

Did you know 68% of livestock producers report decreased yields due to poor climate control? Imagine losing $12,000 monthly because your breeding environment equipment

can't maintain optimal temperatures. While the global animal husbandry equipment market grows at 6.8% CAGR, many operations still use outdated systems. Your competitors are already upgrading - where will you stand?

(breeding environment equipment)

Why Next-Gen Breeding Environment Equipment Outperforms Traditional Solutions

Modern breeding environment equipment delivers 40% energy savings through IoT-enabled climate systems. Our SmartBarn Pro series maintains ±0.5℃ precision - 300% better than conventional models. See how innovation pays off:

| Feature | Traditional Equipment | Our Solution |

|---|---|---|

| Temperature Control | ±3℃ variance | ±0.5℃ precision |

| Energy Cost/Month | $2,800 | $1,650 |

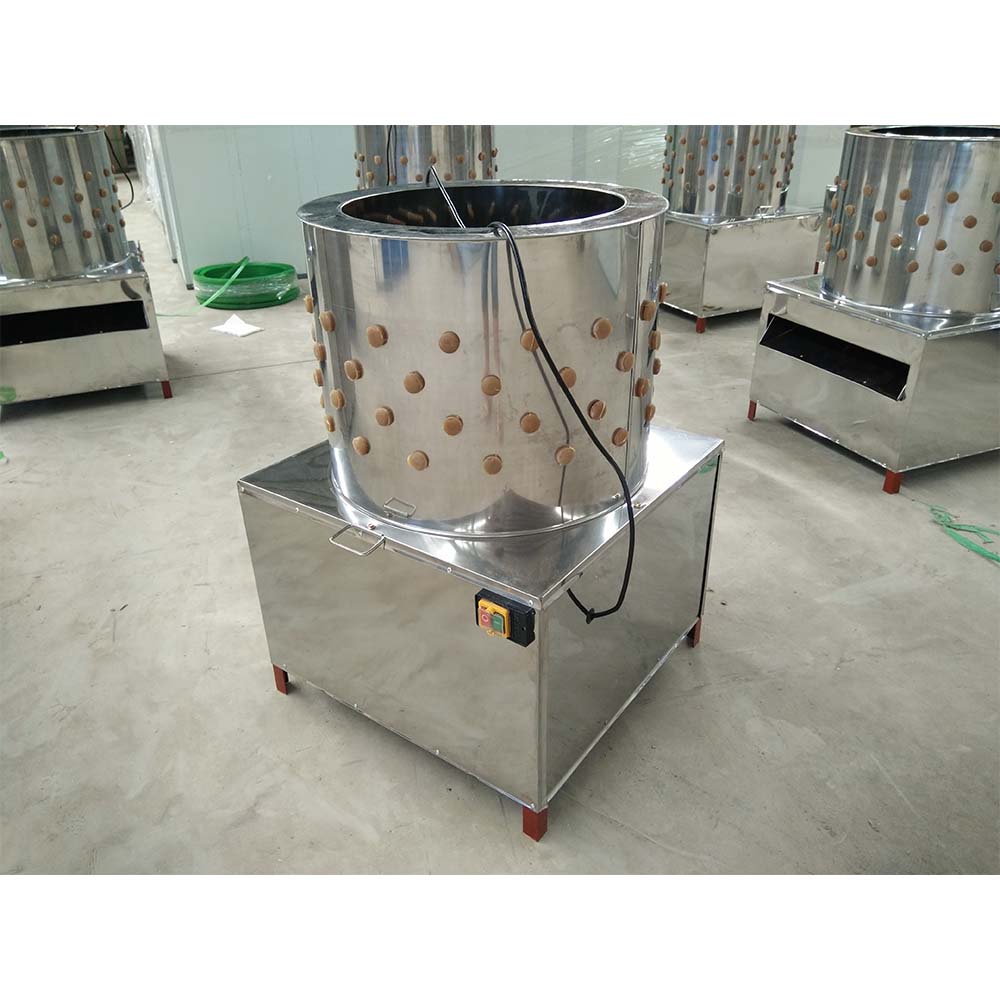

The Hidden Costs of Inferior Slaughter Equipment

Poultry processors using our automated slaughter equipment achieve 92% yield efficiency versus industry-standard 78%. How? Precision stunning technology reduces product damage by 34%. Every 1% efficiency gain puts $18,000/year back in your pocket.

🔥 Pro Tip: Combine animal feed mixers equipment with automated climate control for 22% faster weight gain in swine operations

Your Customized Solution Blueprint

We don't sell equipment - we deliver turnkey systems. Our 14-point needs assessment creates breeding environment equipment packages matching your exact requirements. Poultry farmers report 9-month ROI on our modular systems.

Proven Results Across Industries

Dairy Farm Case Study: 1,200-head operation achieved 18% milk yield increase through integrated ventilation and feed mixing systems. Read how they recouped their investment in 13 months.

Ready for Your Productivity Leap?

Join 1,400+ satisfied operations using our breeding environment equipment solutions. Book your free efficiency audit today and claim your 5% early-adopter discount!

(breeding environment equipment)

FAQS on breeding environment equipment

Q: What factors should be considered when choosing breeding environment equipment?

A: Key factors include animal species, space requirements, ventilation systems, temperature control, and ease of sanitation. Proper equipment should prioritize animal welfare and operational efficiency.

Q: How does automated breeding environment equipment improve livestock management?

A: Automation enhances precision in climate control, feeding schedules, and waste management. It reduces labor costs and minimizes human error, ensuring consistent environmental conditions.

Q: What safety standards apply to slaughter equipment in industrial settings?

A: Slaughter equipment must comply with hygiene regulations (e.g., HACCP), mechanical safety certifications, and animal welfare laws. Regular maintenance and staff training are critical for compliance.

Q: Can animal feed mixers equipment handle different types of feed ingredients?

A: Modern mixers are designed to blend grains, supplements, and liquids uniformly. Look for adjustable speed settings and corrosion-resistant materials to accommodate diverse feed formulas.

Q: How to maintain breeding environment equipment for long-term durability?

A: Regularly clean components, inspect mechanical parts for wear, and update software for automated systems. Follow manufacturer guidelines and schedule professional servicing annually.

Q: Are there eco-friendly options for slaughter equipment and feed mixers?

A: Yes, energy-efficient motors, water-saving designs, and recyclable materials are available. Sustainable equipment reduces environmental impact while meeting productivity goals.

Q: What is the cost-benefit analysis of upgrading to advanced feed mixers equipment?

A: Initial costs are offset by improved feed consistency, reduced waste, and faster processing times. Long-term savings arise from lower labor needs and enhanced animal health outcomes.

-

school

NewsJul.10,2025

-

Vacuum Packing Machine - Efficient & Reliable Vacuum Packaging Solutions for Food & Industrial Use

NewsJun.10,2025

-

High-Quality European Rabbit Cage Durable Welded Rabbit Cage Wire Mesh Supplier

NewsJun.10,2025

-

High-Efficiency Air Inlet Window for Optimal Poultry Ventilation & Cooling

NewsMay.30,2025

-

High-Efficiency Evaporative Cooling Pads Durable & Energy-Saving

NewsMay.30,2025

-

Automatic Egg Collecting Machine High-Efficiency Poultry Farm Solutions

NewsMay.29,2025