egg tray molding machine

12 月 . 20, 2024 01:58 Back to list

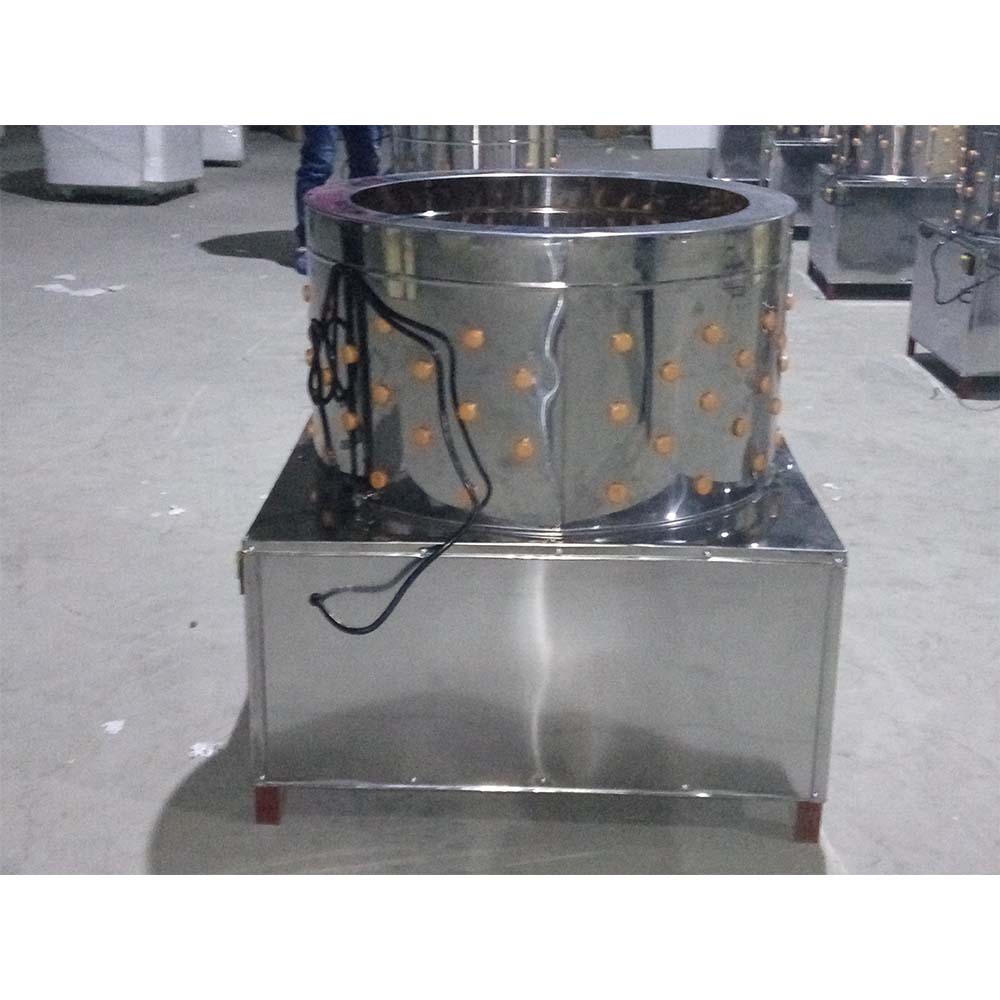

egg tray molding machine

The Advancements and Benefits of Egg Tray Molding Machines

In the world of sustainable packaging, egg tray molding machines have emerged as a significant technological advancement. These machines are specifically designed to produce egg trays and other forms of molded pulp packaging efficiently and cost-effectively. As the demand for eco-friendly packaging solutions surges, the role of egg tray molding machines becomes increasingly important.

Understanding the Technology

Egg tray molding machines utilize a process called pulp molding, which involves the recycling of paper waste, such as newspapers, cardboard, and other cellulose materials. These materials are first blended with water to create a slurry. The slurry is then poured into molds, where it takes shape and dries, resulting in lightweight, durable egg trays. These trays are designed to protect eggs during transportation, significantly reducing breakage and waste.

The machinery typically consists of several key components, including a pulping system, a molding unit, a drying system, and a stacking unit. Advanced technologies allow for automation in each phase of production, enhancing efficiency and reducing labor costs. Many modern machines are designed with energy-saving features and can operate on a variety of raw material inputs, making them versatile for different production scales.

Environmental Impact

One of the most significant benefits of egg tray molding machines is their contribution to sustainability. Traditional plastic egg packaging has a detrimental impact on the environment due to its non-biodegradable nature. In contrast, egg trays made from recycled paper pulp are biodegradable and recyclable, making them a more eco-friendly option. This shift toward sustainable materials is essential in combating plastic pollution and reducing carbon footprints.

Moreover, the use of recycled materials not only helps reduce waste but also promotes a circular economy. By utilizing waste paper as raw material, egg tray molding machines encourage recycling efforts and reduce the need for virgin resources. This aligns with global sustainability goals and corporate social responsibility initiatives aimed at minimizing environmental impact.

egg tray molding machine

Economic Advantages

Investing in an egg tray molding machine can provide considerable economic benefits. The initial setup may require significant capital; however, the long-term savings will often outweigh these costs. By producing their own packaging, businesses can reduce expenditures associated with purchasing pre-made trays. Additionally, the versatility of molded pulp products means that companies can diversify their offerings beyond egg trays to include packaging for fruits, vegetables, and other delicate items.

Furthermore, as consumers increasingly prefer sustainable products, businesses that adopt eco-friendly packaging practices can gain a competitive advantage in the market. Public perception is shifting towards brands that prioritize environmental responsibility, resulting in increased customer loyalty and potentially higher profit margins.

Versatile Applications

While egg trays are the primary product, egg tray molding machines are not limited to producing only this item. The technology allows manufacturers to create a wide range of molded pulp products, including fruit trays, beverage carriers, and even industrial packaging materials. This adaptability makes these machines an attractive investment for companies looking to branch out into new markets while still maintaining their focus on sustainability.

Conclusion

Egg tray molding machines represent a convergence of efficiency, sustainability, and economic benefits in the packaging industry. With their ability to utilize recycled materials, these machines play a vital role in reducing environmental impact and promoting a circular economy. As the demand for eco-friendly packaging alternatives continues to grow, investing in egg tray molding technology not only makes sense from an environmental perspective but also offers substantial economic advantages. Businesses that embrace this technology are not only contributing to a more sustainable future but also paving the way for innovation and profitability in an ever-evolving marketplace. The future of packaging is here, and it is molded from recycled paper pulp.

-

school

NewsJul.10,2025

-

Vacuum Packing Machine - Efficient & Reliable Vacuum Packaging Solutions for Food & Industrial Use

NewsJun.10,2025

-

High-Quality European Rabbit Cage Durable Welded Rabbit Cage Wire Mesh Supplier

NewsJun.10,2025

-

High-Efficiency Air Inlet Window for Optimal Poultry Ventilation & Cooling

NewsMay.30,2025

-

High-Efficiency Evaporative Cooling Pads Durable & Energy-Saving

NewsMay.30,2025

-

Automatic Egg Collecting Machine High-Efficiency Poultry Farm Solutions

NewsMay.29,2025