floating feed making machine

2 月 . 07, 2025 02:09 Back to list

floating feed making machine

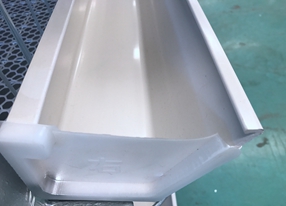

The floating feed making machine plays a pivotal role in the aquaculture industry, significantly influencing both productivity and sustainability. Having a firsthand experience with this state-of-the-art equipment provides a comprehensive understanding of its operational advantages and potential applications. Designed with cutting-edge technology, the floating feed making machine ensures uniform feed quality, an essential aspect for maintaining optimal fish health and growth rates.

Moreover, its user-friendly interface and customizable settings permit operators to tailor feed production to the specific needs of their aquatic livestock. This flexibility allows for the creation of feeds that enhance fish growth and health, thereby optimizing production outputs. The machine's capacity to integrate with peripheral equipment further enhances its functionality, enabling seamless scaling and adaptation to different production environments. In terms of trustworthiness, the machine is backed by comprehensive technical support and a commitment to continuous improvement based on user feedback. It is designed to meet the highest safety and quality standards, ensuring peace of mind for operators and adherence to regulatory requirements. Manufacturers offer extensive training and maintenance services, solidifying their commitment to customer satisfaction and operational excellence. Users often highlight the floating feed making machine's contribution to economic sustainability. By optimizing feed production, aquaculture enterprises can achieve greater profitability and competitiveness. This machine is not just an asset but a catalyst for innovation in the industry, driving advances in feed science and production techniques. In conclusion, the floating feed making machine represents a convergence of technological innovation and practical application, delivering tangible benefits to the aquaculture industry. Its expert design, authoritative standing in the market, and reliable performance make it an indispensable tool for modern aquaculture ventures seeking to maximize efficiency and uphold environmental stewardship. Embracing this technology translates to more sustainable operations and improved outcomes, paving the way for future advancements in aquaculture feed production.

Moreover, its user-friendly interface and customizable settings permit operators to tailor feed production to the specific needs of their aquatic livestock. This flexibility allows for the creation of feeds that enhance fish growth and health, thereby optimizing production outputs. The machine's capacity to integrate with peripheral equipment further enhances its functionality, enabling seamless scaling and adaptation to different production environments. In terms of trustworthiness, the machine is backed by comprehensive technical support and a commitment to continuous improvement based on user feedback. It is designed to meet the highest safety and quality standards, ensuring peace of mind for operators and adherence to regulatory requirements. Manufacturers offer extensive training and maintenance services, solidifying their commitment to customer satisfaction and operational excellence. Users often highlight the floating feed making machine's contribution to economic sustainability. By optimizing feed production, aquaculture enterprises can achieve greater profitability and competitiveness. This machine is not just an asset but a catalyst for innovation in the industry, driving advances in feed science and production techniques. In conclusion, the floating feed making machine represents a convergence of technological innovation and practical application, delivering tangible benefits to the aquaculture industry. Its expert design, authoritative standing in the market, and reliable performance make it an indispensable tool for modern aquaculture ventures seeking to maximize efficiency and uphold environmental stewardship. Embracing this technology translates to more sustainable operations and improved outcomes, paving the way for future advancements in aquaculture feed production.

Latest news

-

school

NewsJul.10,2025

-

Vacuum Packing Machine - Efficient & Reliable Vacuum Packaging Solutions for Food & Industrial Use

NewsJun.10,2025

-

High-Quality European Rabbit Cage Durable Welded Rabbit Cage Wire Mesh Supplier

NewsJun.10,2025

-

High-Efficiency Air Inlet Window for Optimal Poultry Ventilation & Cooling

NewsMay.30,2025

-

High-Efficiency Evaporative Cooling Pads Durable & Energy-Saving

NewsMay.30,2025

-

Automatic Egg Collecting Machine High-Efficiency Poultry Farm Solutions

NewsMay.29,2025