Innovative Semi-Automatic Egg Tray Machine for Efficient Production and Cost Savings in Manufacturing

8 月 . 14, 2024 06:21 Back to list

Innovative Semi-Automatic Egg Tray Machine for Efficient Production and Cost Savings in Manufacturing

The Semi-Automatic Egg Tray Machine Revolutionizing Packaging Solutions

In recent years, as environmental concerns rise, industries are increasingly looking for sustainable solutions to their packaging needs. One innovative development in this field is the semi-automatic egg tray machine, a technology that is changing the way eggs are packaged and transported. This machine not only addresses the need for efficient production techniques but also promotes the use of eco-friendly materials.

What Is a Semi-Automatic Egg Tray Machine?

A semi-automatic egg tray machine is designed to produce egg trays from recycled paper pulp. The majority of these machines operate on a simple process raw materials like waste paper, cardboard, and newsprint are mashed into a slurry, molded into trays, and then dried to form durable packaging. Unlike fully automatic machines, semi-automatic models allow for greater operator control, making them ideal for small to medium-sized businesses looking to balance productivity with labor costs.

Key Advantages

1. Cost-Effective Production One of the main benefits of using a semi-automatic egg tray machine is the lower initial investment compared to fully automatic counterparts. This makes it accessible to small-scale producers who may not have the capital for high-end machinery yet still wish to maintain quality and efficiency in their production process.

2. Eco-Friendly Materials The use of recycled paper in egg trays aligns with global sustainability goals. By utilizing waste materials, producers can reduce their carbon footprint and contribute to environmental conservation. These trays are biodegradable, reducing plastic waste associated with traditional egg packaging.

3. Flexibility and Scalability Semi-automatic machines offer flexibility in production rates, allowing businesses to adjust output based on demand. This adaptability is crucial for smaller enterprises that need to manage fluctuations in sales without overcommitting resources.

4. Quality Control With a semi-automatic setup, operators can closely monitor the production process, ensuring that each tray meets quality standards. This hands-on approach reduces the likelihood of defects and enhances the overall product quality, which is vital for the safe transport of eggs.

semi automatic egg tray machine

The Production Process

The operation of a semi-automatic egg tray machine involves several key steps

1. Pulping Waste paper is shredded and mixed with water to create a slurry. 2. Molding The slurry is poured into a mold to form the shape of the egg tray. The flexibility in molds allows for the production of various tray designs. 3. Drying The molded trays are transferred to a drying unit, either using natural sunlight or equipment, depending on the location and climate. 4. Trimming and Packing Once dried, the trays are trimmed and packed for distribution.

Market Demand and Future Prospects

The demand for eco-friendly packaging solutions continues to grow, driven by consumer preferences and regulatory changes. As the poultry industry expands, so does the need for efficient and sustainable packaging methods. The semi-automatic egg tray machine not only fills this gap but also provides businesses with a competitive edge in a market that increasingly values sustainability.

Moreover, advancements in technology will likely enhance the capabilities of semi-automatic machines. Features such as improved energy efficiency, automated drying processes, and better pulp grinding techniques can further streamline production.

Conclusion

The semi-automatic egg tray machine stands at the forefront of the sustainable packaging movement within the egg industry. By revolutionizing the way eggs are packaged, it provides businesses with a practical solution that aligns with ecological initiatives and market demands. With its cost-effectiveness, quality control, and eco-friendly production advantages, this technology is set to play a significant role in the future of sustainable packaging. As we move forward into an era where environmental stewardship is vital, innovations like the semi-automatic egg tray machine will be instrumental in shaping a more sustainable future.

-

school

NewsJul.10,2025

-

Vacuum Packing Machine - Efficient & Reliable Vacuum Packaging Solutions for Food & Industrial Use

NewsJun.10,2025

-

High-Quality European Rabbit Cage Durable Welded Rabbit Cage Wire Mesh Supplier

NewsJun.10,2025

-

High-Efficiency Air Inlet Window for Optimal Poultry Ventilation & Cooling

NewsMay.30,2025

-

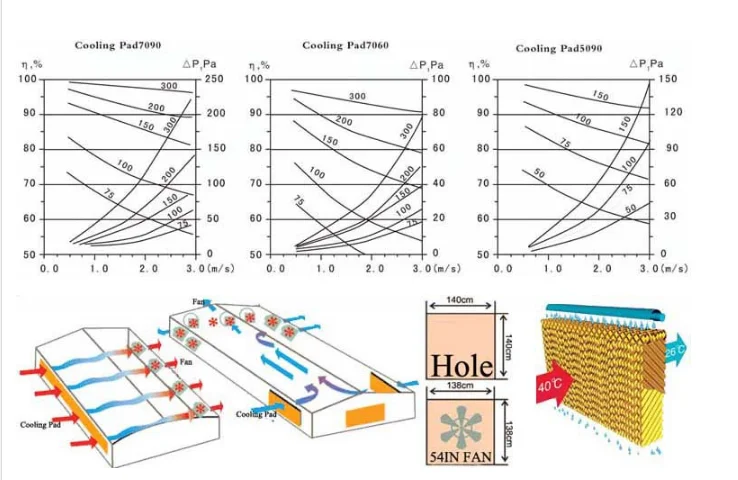

High-Efficiency Evaporative Cooling Pads Durable & Energy-Saving

NewsMay.30,2025

-

Automatic Egg Collecting Machine High-Efficiency Poultry Farm Solutions

NewsMay.29,2025